Thermo Bond Buildings is a manufacturer of equipment shelters in South Dakota, United States. Products range from small 10 square foot buildings to double-wide trailer-length shelters. Thermo Bond Buildings has been using Fishbowl since 2011.

ThermoBond Buildings

[Business Challenges]

For many years, telephone companies built their own equipment shelters using an in-house construction team until Thermo Bond Buildings established in 1990. Thermo Bond’s goal was to manufacture these shelters in a single facility with a unique twist: everything a telecom company would need in this shelter would be fitted inside prior to delivery. The company added tremendous value to the telecom industry, spurring other competitors to copy their business model.

As their business grew, they purchased Fishbowl in 2010 and implemented in 2011. At the time, the volume of work was manageable and the team was able to create sales orders, bill of materials, and purchase orders on their own.

In 2018 the company started the year with new ownership, a new executive team, and a much larger business. With their growing business volume, the company’s biggest problem was the use of Excel in their process.

Thermo Bond was utilizing Excel for all of their project planning and quoting. A customer would begin the design process through an Excel workbook that allowed the company to estimate its labor and material costs. Then, the sales team would propose a sales number to the customer based on those costs. Unfortunately, those costs were inaccurate. The company had targeted a gross profit of 25% per project, yet they were yielding only around 11%.

Thermo Bond requested the help of Israel Lopez Consulting (ILC) to visit on-site to review the situation with the executive team. During that first visit, ILC identified the following challenges with Thermo Bond’s current process:

- The sales team had their own special Excel workbook that they would make a copy of to start similar projects.

- Each workbook had an estimated cost for materials based by formula instead of exact item quantity and cost.

- The engineering team could not see what material was needed in the pipeline until a project was accepted by the customer.

[Solutions]

ILC addressed Thermo Bond’s challenges in three parts: an improved sales quoting experience, improved project scheduling, and business intelligence reporting to aid in uncovering project margin erosion.

Quote Plugin

ILC proposed a new experience for sales quoting that was vastly superior to, and more accurate than, the existing Excel workbook. ILC built a custom plugin in Fishbowl’s Sales Order module that allowed for a “Design to Order” workflow screen to appear, leveraging the best parts of Fishbowl’s Manufacturing process and minimizing the time it took to provide exact manufacturing costs. The plugin allowed a sales person to start a quote, follow a set of prompts (managed by the engineering team), and finish with the most up-to-date labor and material costs. It also provided the company with a target gross margin to estimate the best selling price for each project. ILC added file and save functionality as well which allowed quotes to be managed over the entire quoting cycle; thus, when a quote was accepted, it would import the Bill of Materials, Part, Product, and Sales Order into Fishbowl with just one click.

SmartSheet Integration

Once quotes were accepted and imported into Fishbowl to schedule for manufacturing, another problem presented itself: live project scheduling. Scheduling for a company can be a bit tricky and Thermo Bond was no different. They were happy to solve their scheduling workflow by using SmartSheet, but SmartSheet did not link with Fishbowl. To solve this, ILC built a simple integration to pull Work Order scheduling dates from SmartSheet into Fishbowl to enable a better picture of future material needs.

Custom Business Intelligence

In the process of providing more accurate quotes, another type of problem was discovered through the custom quote plugin: project margin erosion. It was not enough to properly price out a project, but the team had to identify what was causing a project to lose 5% margin over its six-month lifespan. ILC built a series of reporting tools to capture original project costs by department, and compare them with Quote costs, Project Start costs, and “As-Built” costs. This enabled the engineering team to tighten its Bill of Material templates for ordinary materials not included in the quoting process that caused costs to erode.

[Results]

Improved Product Gross Margin

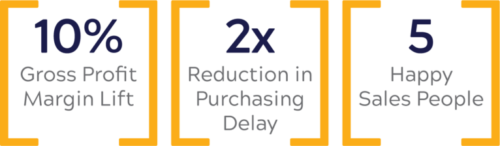

Since the implementation of the quote plugin, the sales team at Thermo Bond was no longer fighting to maintain margin with operations (as the Excel workbook they used was generating a margin that was impossible to meet). The sales team also saw great improvements with customer conversations in real time; a sales person could tell a customer in about 10 seconds if a design change request would increase or decrease the cost of their project, and then the sales person could verify the new cost and lock in the difference.

Reduced Quote to Purchasing Cycle and Reduced Costs

A quote previously took 10-14 days to review because of the long delays between three different teams. Now, quotes spend about 2-4 days in review by the engineering team since the material costs on newly created projects by the quote plugin are incredibly accurate. This also allowed for the purchasing team to stay ahead of manufacturing, locking in better material costs.

Sales and Operations Harmony

After ILC’s solutions were implemented, sales and operations teams were on the same page. Each team had the tools it needed to effectively communicate the exact data necessary to execute a project on-time and on-budget. As a result, the teams experienced an improvement in their workflow as well as a reduction in stress and anxiety related to communication and “project fire fighting.”

Company

ThermoBond Buildings

Industry

Manufacturing

Challenges

- Project Cost Overruns

- Critical Item Stockouts

- Scheduling Confusion

Solutions

- Quote Plugin

- SmartSheet Integration

- Custom Business Intelligence

Results

- Improved Product Gross Margin

- Reduced Quote to Purchasing Cycle and Reduced Costs

- Sales and Operations Harmony

“Without ILC, we would still be quoting $80k projects in Excel.”

― Michael Kastning